Maintenance

TA Management

With more than 30 years of experience, skills, and expertise, YuhanTech manages the budget, process, and organizational structure planning and implementation required for design, purchase and construction from contract stage to Pre TA, Main TA and Commissioning and will become the leader in the Total Maintenance Service field

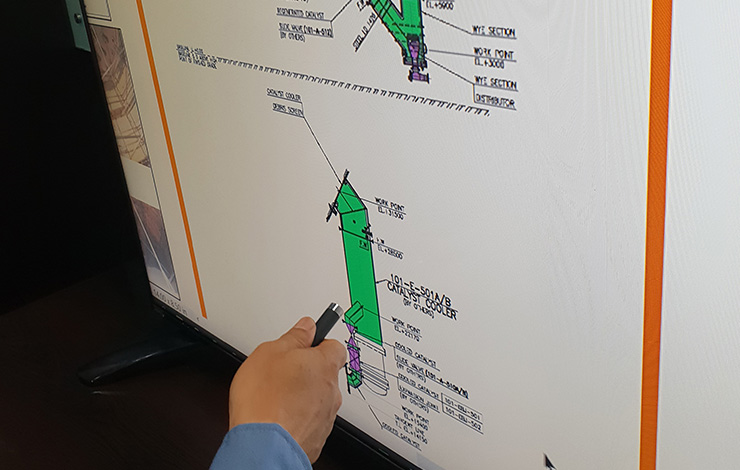

TA project

YuhanTech conducts comprehensive TA every year for its customers, including machinery, piping, steel frame work, Catalyst Handling, and device cleaning. Through this, we successfully complete all the tasks requested by the customer through specialized core manpower input and multiple project simulation processes, enhancing the production efficiency and stability of the customer's plant facilities.

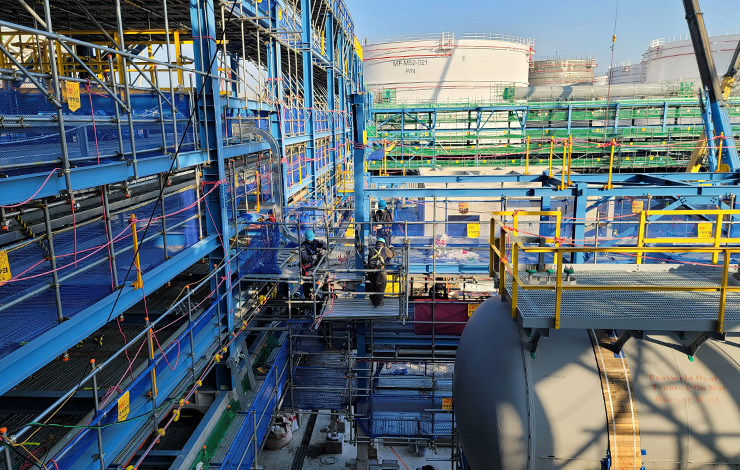

Daily maintenance

YuhanTech resides in the long term contact base at the refinery/petrochemical customer facilities to ensure customer satisfaction with regular maintenance and special maintenance as the best quality and safety priority

- GS Caltex, LG Chem, Lotte Chemical (Yeosu)

- HD Hyundai Oilbank, LG Chem, Hanwha TotalEnergies, Lotte Chemical (Daesan)

- S-Oil, SK Energy (Ulsan)

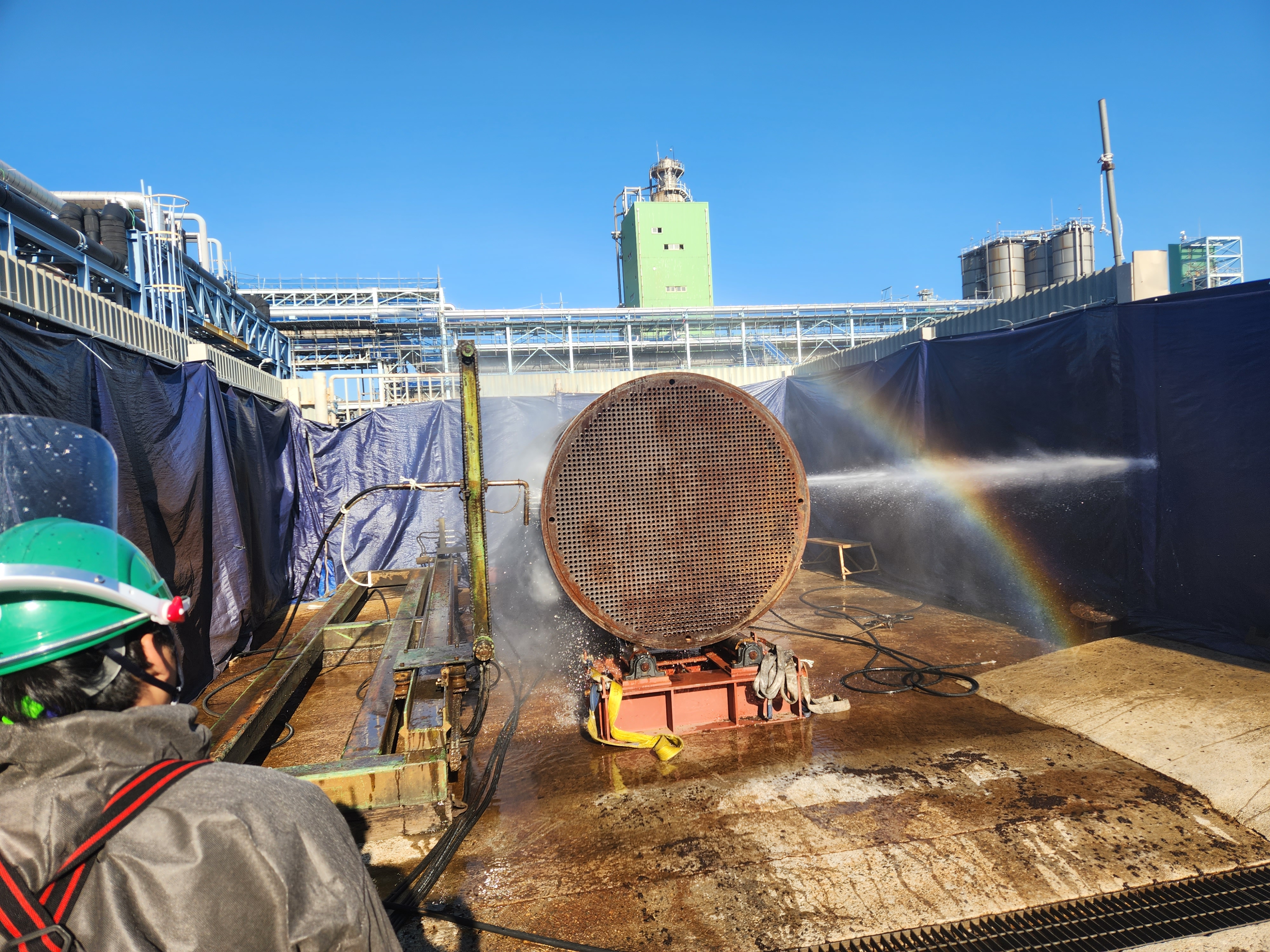

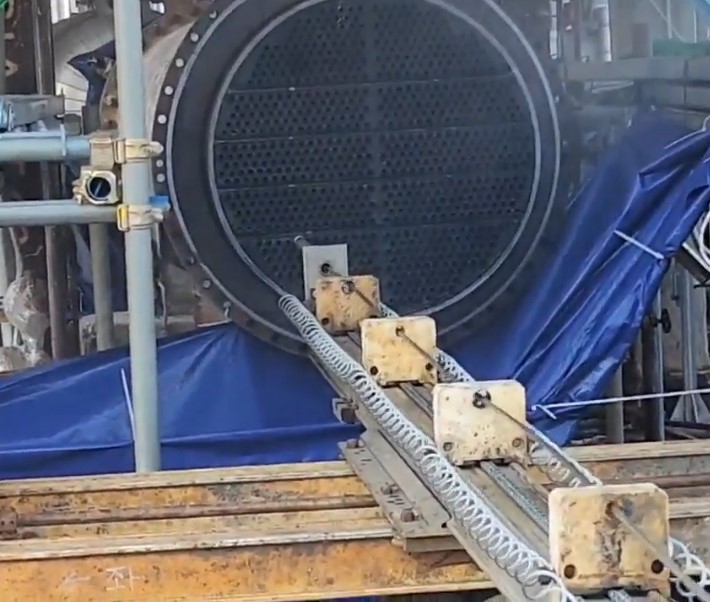

Waterjet Cleaning

The Waterjet Cleaning offers an eco-friendly and efficient cleaning maintenance methods. This system uses high-pressure water to clean surfaces, effectively removing contaminants without the use of chemicals.

YuhanTech has contributed to the safety and productivity improvement of industrial sites through the accumulated Knowhow during 30years.

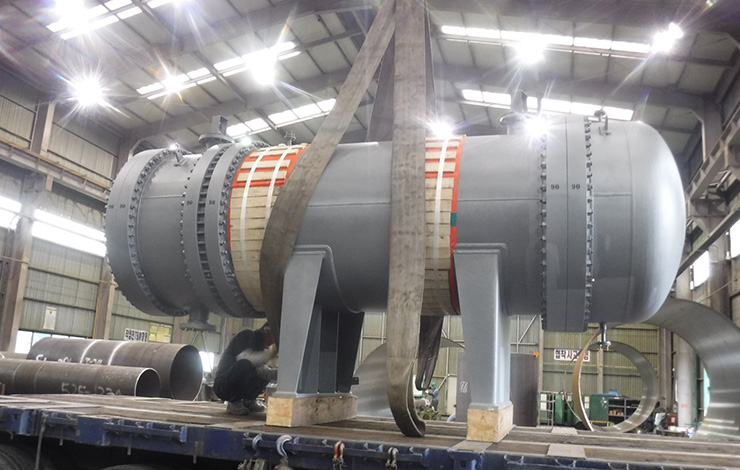

Equipment Fabrication

We operate our own fabricating shop with ASME "U" & "S", The National Board "R" & "NB" quality certification to respond customized to requests for fabricating pressure vessel and heat exchangers due to small orders from customers. We also fabricate heat exchangers (Shell & Tube Type), Column, Drum, Vessel, Storage Tank, pressure vessel modification, new device fabricating and licensing for Field remodeling inspection.